News

Tuesday, January 12, 2021

How does SLS 3D printing work?

SLS 3D printing uses a high-powered laser to fuse powdered thermoplastic material together into a desired 3D shape. SLS relies on the principle of “sintering” a material to form a solid mass. Sintering refers to the process of compacting a loose material, such as a plastic powder, by the application of heat or pressure. Sintering does not melt the material, but rather provides just enough energy for the atoms of separate objects to diffuse across the material boundaries. SLS produces tough, functional parts, with the ability to achieve good surface finish, fine detailing and (almost) no geometrical constraints, as it doesn’t need support material.

This production-grade technology is ideal for both functional prototyping and small production runs, as it offers a high degree of design freedom, high accuracy, and exceptional mechanical properties to rival those of injection-molded parts.

Monday, January 11, 2021

Expand passion for 3d technologies @ International Hellenic University - XYZ Printing | Da Vinci Pro |

We are very happy every time we can share our passion for Additive Manufacturing and we support young & creative students to expand their knowledge in 3D technologies!

Tuesday, January 5, 2021

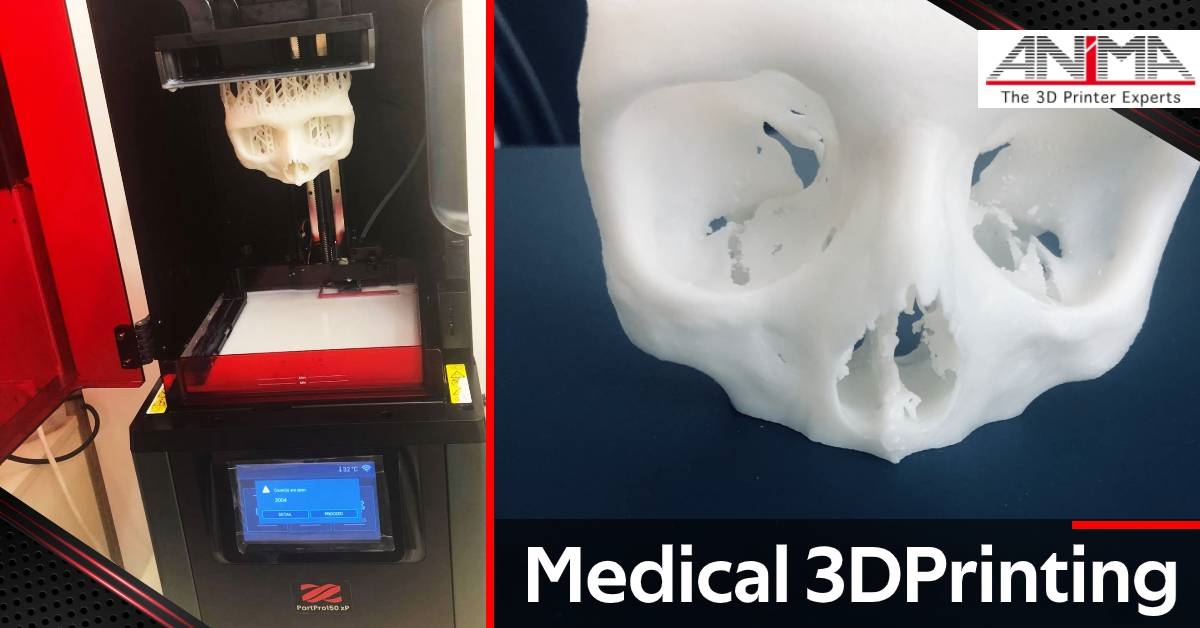

MEDICAL 3D PRINTING

We are proud every time Additive Manufacturing is used in order to support the Medical Industry. We also feel happy when 3D technology is used to make people's lives better!

Nowadays, the Medical sector has increasingly relied on 3D printed skulls to prepare for surgery before proceeding with challenging situations, such as treating adults that have suffered from severe trauma caused by violent accidents.

The first step is obtaining personalized data taken from a computerized tomography, commonly known as a CAT scan, to make an electronic 3D design of the patient’s skull. The next crucial step is printing the skull in a three-dimensional, life-size model. The print is used as a 100% accurate model so that the surgeon can practice the procedure.

This translates to faster operation times, smaller incisions, less blood loss and of course elimination of uncertainty. The skull was created by using an #XYZ Printing PartPro 150xp 3D printer from ANiMA’s well-experienced engineers. 😊 Well Done ANiMA team!

Tuesday, January 5, 2021

Coherent Creator: Ideal for Research!

#Coherent Creator:

Ideal for Research! #Made in Germany

Advantages:

• Open material platform giving the ability to use different materials

• Ability to adjust the printing parameters on the fly

• Advanced operating software & user friendly interface

• High construction speed by 30% faster compared to similar systems on the market

• High accuracy, detail and finish of the final pieces due to the variable spot size

• Easy creation of metal parts in any geometry (something not possible with the traditional construction methods)

• Unique innovative rotary recoating system

• Ability to print on Reactive materials *

* Creator RA model

See more: https://lnkd.in/dW5yD9d

https://lnkd.in/dXFGV6

Contact us today and learn more about their operation and characteristics!

#email us : info@anima.gr

Thursday, July 30, 2020

Announcement: Competitiveness Toolbox

Announcement: Competitiveness Toolbox

Thursday, April 2, 2020

COVID 19 Response Page

COVID 19 Response Page