Features

ProM IS 500 comes with an entire ecosystem of software that includes Aura as well as new software for design and simulation. This makes it easy to switch from our desktop 3D printing solution Composer to ProM IS.

- The open material system allows continuous carbon fiber reinforcement with engineering-grade plastics such as PA and PC, as well as high-performance plastics such as PEEK, PEKK, PEI, etc., and materials for support structures. The database will be updated with new materials and verified profiles regularly.

- A tool changer for up to four printheads with CCF and FFF extruders, that are also capable of handling tools for inserts and probes as a customization option.

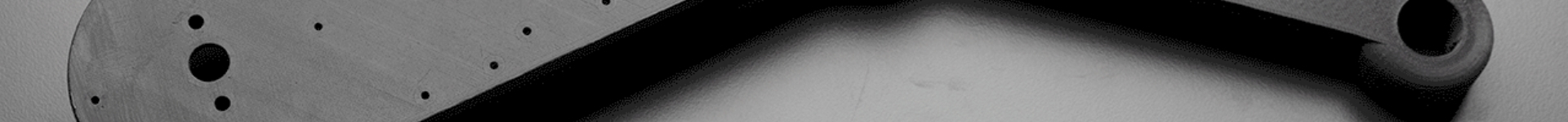

- Flexible fiber trajectories including lattice structures with various parameters as well as topology and material optimization by the Additive Flow’s Formflow and Aura workflow for the best weight-to-strength ratios for parts.

- Adjustable manufacturing volume of lightweight high-loaded parts with complex shapes, such as for UAVs and drones, service robotics, urban mobility, commercial and private space exploration, and more.