The Economics of Additive Manufacturing in Production

When and how 3D printing outperforms traditional methods

Introduction

Additive manufacturing has already proven its ability to create parts that were once considered impossible. But when it comes to industrial production, the question is less about what can be built and more about whether it makes financial sense to do so. For a factory manager or operations team, the decision to integrate metal or polymer additive systems comes down to economics.

Understanding when additive manufacturing (AM) outperforms conventional methods such as machining, casting, or injection molding requires more than a simple cost-per-part comparison. Factors like tooling, downtime, inventory, and time-to-market all play a role in determining the real return on investment.

This article explores the financial logic behind adopting AM for production and how the right technologies and processes can make it not just a viable option but, in many cases, the most competitive one.

When is AM More Cost-Effective than Traditional Manufacturing?

The economics of production usually start with a straightforward metric: the cost of each part. Traditional processes are optimized for scale. Casting a million identical parts will nearly always be cheaper than printing them, at least if unit cost is the only metric considered. But this logic begins to shift when you move to smaller runs, complex geometries, or parts that require frequent design changes.

Additive eliminates many fixed costs upfront. There is no need for molds, dies, or jigs before production begins. A machine can switch from one part to another simply by changing a digital file, without weeks or months of lead time. In applications where flexibility matters, AM often outpaces traditional methods by cutting down on setup costs and avoiding idle capital tied up in tooling.

The value isn’t just in avoiding cost - it’s in building agility into a production line. Manufacturers who operate in markets with rapidly evolving designs, seasonal demand, or customized products see AM’s cost advantage much earlier than those focused solely on high-volume, uniform output.

Cost-Per-Part Dynamics at Low, Medium, and High Volumes

At low volumes, additive is the clear winner. Printing ten specialized brackets for an aerospace test assembly is far more cost-efficient than machining them from billet or designing tooling for casting. Here, AM works as a bridge between prototyping and early production.

At medium volumes, the analysis becomes more nuanced. This is where machine throughput and process efficiency matter most. Dual-laser systems like the iSLM350D Ultimate reduce build times significantly, lowering the cost-per-part to levels that are competitive with machining, especially for complex shapes or high-value metals. Factoring in post-processing, inspection, and qualification is essential, but the overall cost structure often remains favorable compared to traditional subtractive methods when geometries are optimized for AM.

The Industrial Grade Metal 3D Printer iSLM350D Ultimate

At high volumes, traditional mass production still dominates, especially for simple parts where tooling costs are spread thinly across thousands or millions of units. But even here, AM finds its niche. For instance, it can be used to supplement production during ramp-up or to address supply chain bottlenecks while conventional lines scale up.

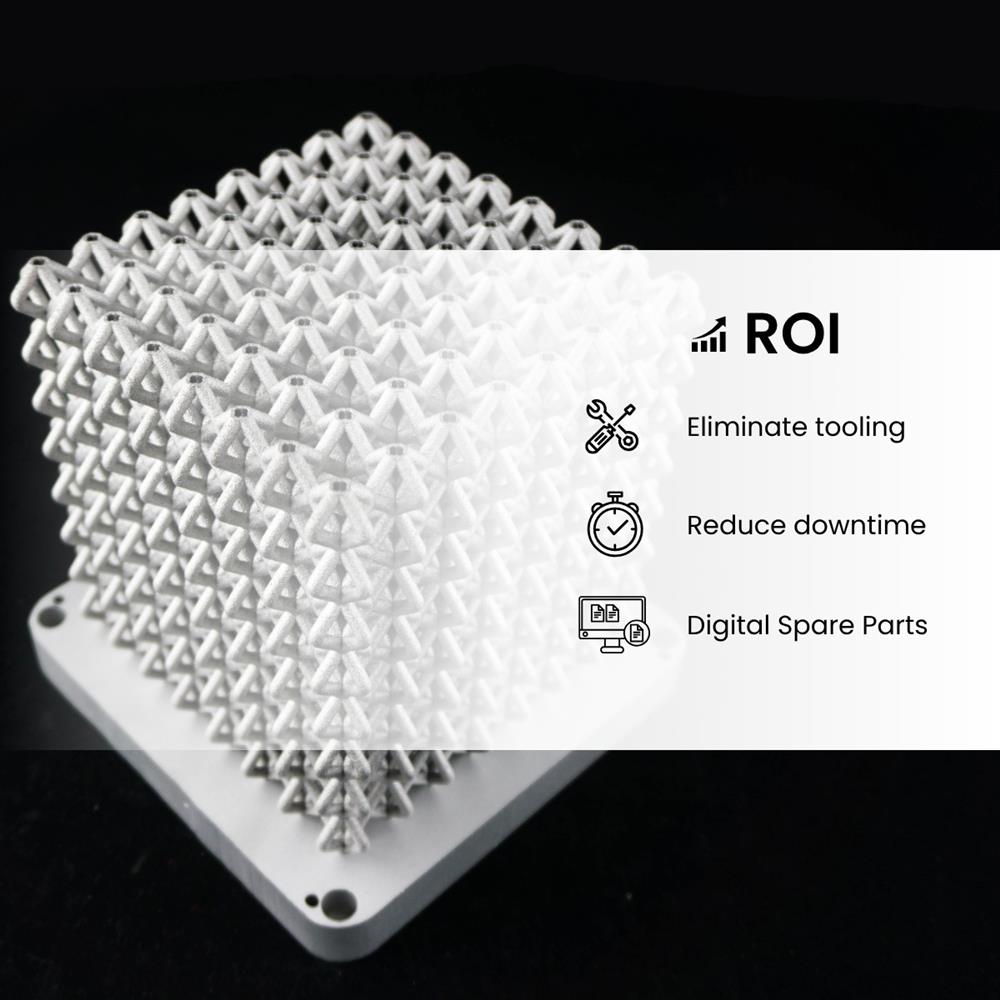

Hidden ROI: Eliminating Tooling, Reducing Downtime, and Enabling Digital Spare Parts

Tooling is often the largest hidden cost in manufacturing. Designing, machining, and maintaining molds or fixtures consumes both money and time. AM removes this layer entirely, replacing physical tooling with digital flexibility. That means fewer sunk costs and less capital tied up in tools that may only be used for a short production run.

Downtime is another overlooked factor. In traditional setups, when a tool breaks or a mold wears out, production halts until a replacement can be made. With AM, digital spare tools or replacement fixtures can be printed on demand, significantly reducing downtime and lost revenue.

Digital spare parts extend this principle into inventory. Instead of stocking warehouses with rarely used components, manufacturers can store files and produce parts only when needed. This reduces storage costs, lowers the risk of obsolescence, and creates a leaner supply chain. The financial benefit here is not just in cost avoidance but in resilience - something many industries learned the hard way during recent global supply disruptions.

How Open-Material Systems Help Reduce Lock-In and Optimize Spending

Material choice directly impacts the economics of AM. Some systems restrict users to proprietary powders or resins, locking them into premium prices. Open-material platforms, such as those offered by ZRapid, allow engineers to source from multiple suppliers or even qualify custom alloys.

This flexibility reduces long-term costs, particularly when operating at scale. For example, a stainless-steel powder sourced from a competitive supplier can cut per-kilogram costs significantly while still meeting quality requirements. More importantly, it prevents dependence on a single vendor, giving manufacturers control over both pricing and supply continuity.

Over the life of a production system, material costs often outweigh the machine investment itself. Open systems give manufacturers the ability to optimize those costs without compromising process stability or part quality.

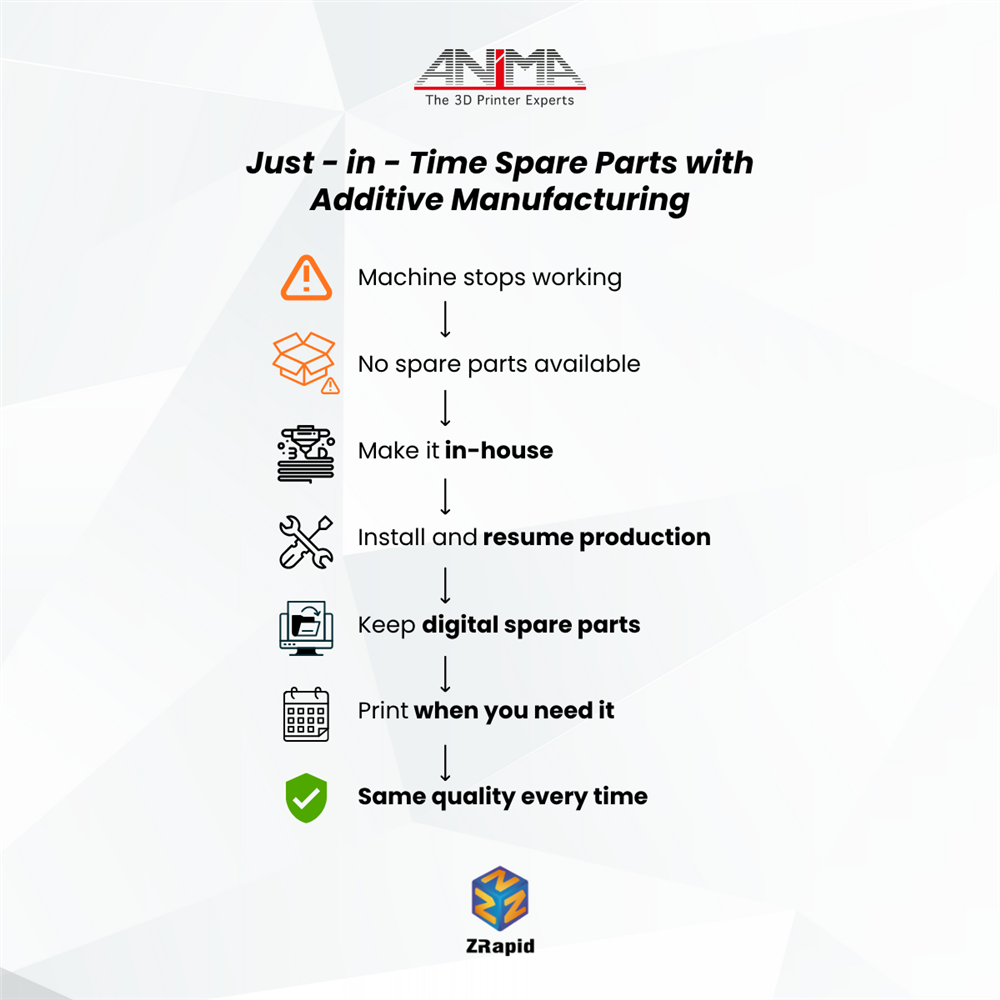

Using AM for Just-in-Time Spare Parts

Consider a production facility that relies on specialized machine components with lead times of 8–12 weeks when ordered from an external supplier. By building a library of validated 3D-printable spare parts, that facility can shift to just-in-time production.

When a machine goes down, instead of waiting weeks for a part to arrive, the replacement can be printed overnight. The savings are twofold: reduced downtime and minimized inventory. Over time, this approach can recast maintenance and spare part management from a logistical burden into a controlled, predictable process.

Printers like the iSLM350D Ultimate are especially well-suited to this task, thanks to their ability to produce complex geometries in metals with production-level reliability. Pairing dual-laser throughput with stable gas recirculation ensures these spare parts are not only produced quickly but with the consistency needed to slot straight into critical equipment.

Going to Market Faster with 3D Printing

Speed to market is often the deciding factor in competitive industries. Whether launching a new consumer product, qualifying a medical device, or rolling out an aerospace assembly, every week shaved from the development cycle has measurable financial impact.

Additive accelerates this process by merging design and production into a single digital workflow. Parts can be validated, adjusted, and printed in real time without the need for tooling changes or supplier delays. Early batches can be printed for market testing, while the same digital files can later be scaled into larger production.

For companies working in sectors with frequent product refreshes or short lifecycles, this agility translates directly into profit. The economics here are not just about reducing cost but rather about capturing revenue sooner.

Conclusion

Additive manufacturing is not a universal replacement for traditional processes, but it does offer a unique economic value proposition when applied strategically. The financial benefits are clearest at low to medium volumes, in environments where flexibility, complexity, and responsiveness matter most. Eliminating tooling, reducing downtime, enabling digital spares, and cutting time-to-market all contribute to an ROI that often surpasses traditional benchmarks.

Systems like the iSLM350D Ultimate, with dual-laser throughput and open-material compatibility, show how technology choices can tilt the equation further in favor of AM. But the real key lies in understanding the broader cost picture, not just the headline cost-per-part. For manufacturers willing to look beyond conventional assumptions, additive manufacturing offers not only technical freedom but also a powerful economic advantage.

Contact us, and our expert team will help you find the best solution tailored to your needs!

Email: info@anima.eu

Contact number: +30 210 77 76 822